ENERGY EFFICIENCY CLASSES TO REDUCE CONSUMPTION

For Manufacturing Application Alone, It’s Predictable That Electric Motor System Account For About 70% Of Electrical Energy Use. As Such Massive Customers Of Electrical Energy, Still Small Improvement Can Guide To Large Power Investments.

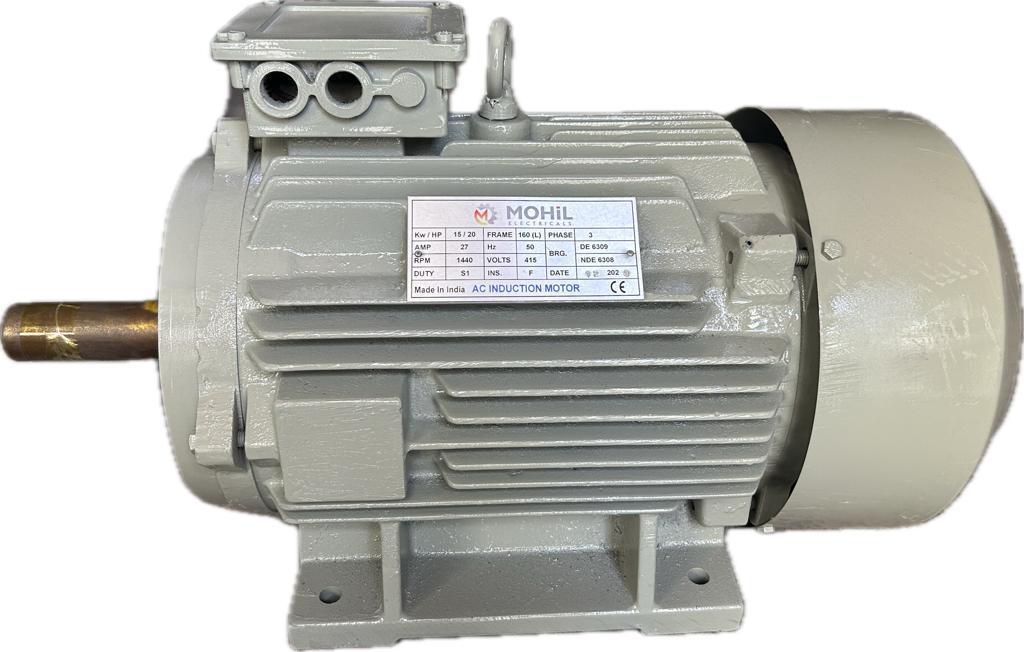

SPECIFICATIONS

Rating Output / K.W. | 0.18 TO 45 K.W. |

Frame Size | 63 TO 225L, 63 TO 225M |

RPM | 3000, 1500, 1000, 750 |

Construction | (B3) FOOT , (B5) FLANGE , (B14) FACE and Combination, B35 FOOT AND FLANGE MOUNTED |

Voltage / Frequency | 415 + 10% / 50 + 5% |

CONSTRUCTIONAL FEATURES

Frame | Cast Iron for Motors in 63 to 180 frames with rugged construction |

End shields | End shields are with Cast Iron |

Terminal Box | Position on top box motors in 63 to 225 frame. Terminal box can be rotated in the step of 90 through 360° for desired cable entries direction. Cable gland suitable to 3/4" to 1" with BS conduit threading |

Shaft | Material EN8 with threaded center for locking of pulley / gear |

Bearings | Double Seal Ball Bearings capable of taking axial loads in both the directions at high speeds |

Protection | IP-55/44 by means of `V' ring seals and oil seals to prevent penetration of solid contaminants / moisture into the motor |

Momentary Overload | 1.6 times of rated torque for 15 seconds |

Insulation class | F' class with temp rise limited to `B' class |

Rotors | Squirrel cage, Aluminum pressure die cast dynamically balanced with half key to maintain low. vibration levels |

Winding | Wound with class `F' copper wire and impregnated with class `F' varnish |

Electric supply & variations | 415V ±10%, 50Hz ±5% and combined variations ±10% unless otherwise specified |

Duty | Continuous (S1) |

Starting Up | 5 seconds for 2 starts from cold conditions |

Service factor | Service factor 1.1 at rated voltage and frequency with class `F' temp. rise |

Ambient Temp | 40°C |